MAHLE’s Sustainability Efforts Lands it on Environmental ‘A List’

The group was able to further reduce CO2 emissions in its production, supply chain & products in 2024…

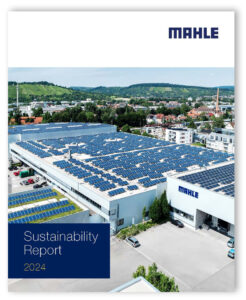

MAHLE Group made major progress on its sustainability efforts last year, landing the automotive parts supplier on an “A list” for climate accountability. The company reports making strides in reducing CO2 emissions in its production, supply chain and product categories.

The successes were recognized by independent organization CDP (Carbon Disclosure Project) for the first time, adding MAHLE to its international A List of companies that take a “holistic” approach to environmentally sustainable business objectives.

“Sustainability is implemented in the group’s key business processes and is a crucial field of action in the implementation of our strategy, MAHLE 2030+,” said Georg Dietz, member of the management board of the MAHLE Group, responsible for sustainability, health, occupational safety and environmental management and the publication of the MAHLE 2024 Sustainability Report.

As materials have been used more efficiently in production and packaging processes, the report shows 80% of the company’s total waste generation can now be reused or recycled. To increase transparency within the supply chain, MAHLE has introduced environmental, social and governance (ESG) “quick checks” to comprehensively check and optimize the environmental, social and governance efforts of its suppliers.

As of 2024, studies show MAHLE has been able to reduce CO2 emissions from the combustion of fossil fuels (Scope 1) and the purchase of electricity procured externally (Scope 2) by 47%, nearing its goal of a 49% reduction by 2030 in comparison with the base year of 2019. It also reduced emissions from the upstream value chain and product usage phase (Scope 3) by 17%, according to officials.

“In order to identify and quantify further energy saving potential, MAHLE is working with energy sprints (time-bound energy-focused initiatives and projects), which are now being carried out worldwide with great success,” said Kathrin Apel, director corporate sustainability, health, occupational safety and environmental management at MAHLE.

Finally, in the area of occupational safety, MAHLE reduced the accident rate in its plants to 2.1 accidents per 1 million hours worked. This includes all accidents resulting in at least one day away from work.

In 2024, the focus was on measures to improve machine safety. MAHLE has had its occupational health and safety management system certified in accordance with ISO 45001 at seven more locations. This means that a total of 114 production locations and seven tech centers are now certified, which accounts for almost 90% of employees.

“For us, the best possible safety at work is non-negotiable,” said Apel.