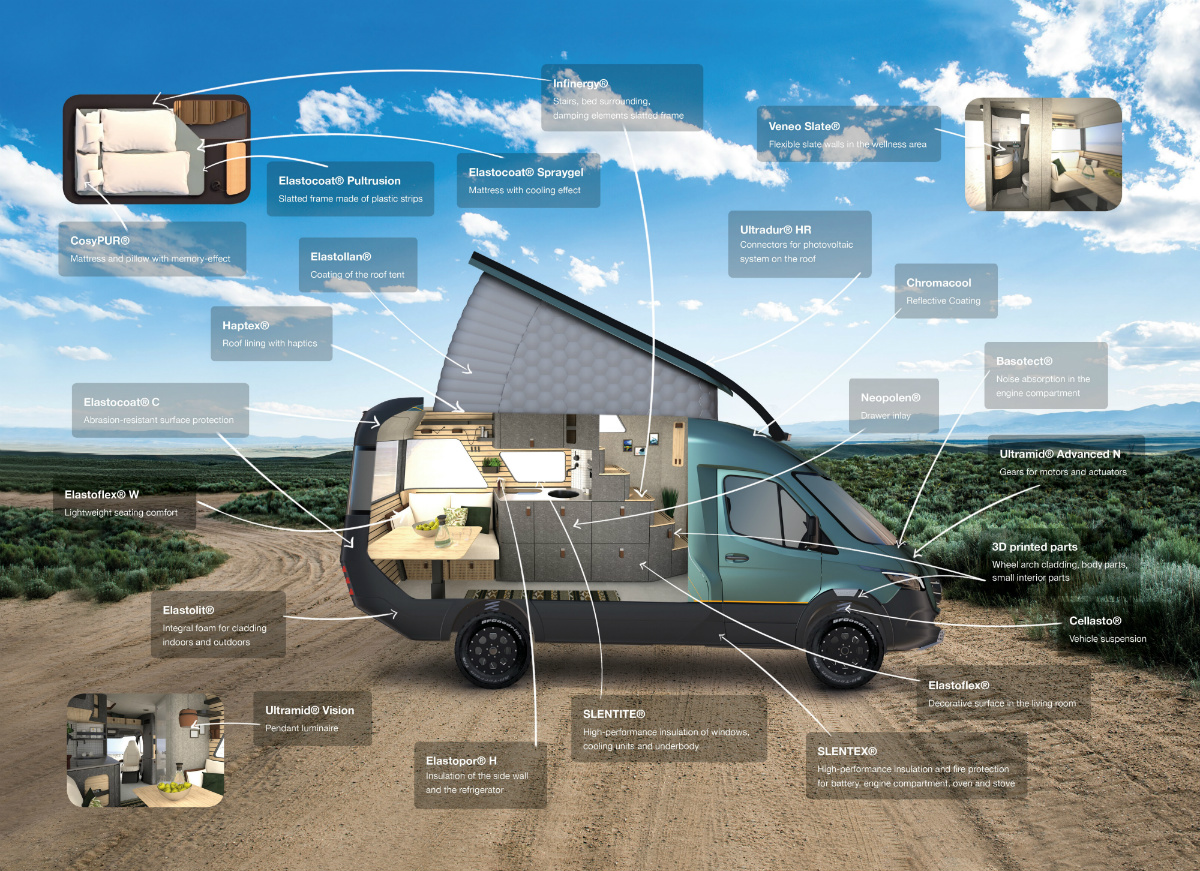

Hymer and BASF Team Up for Campervan Concept Vehicle

The VisionVenture, co-created by BASF and Hymer, is a near-production glimpse into the future of van life. Partnering with the BASF Creation Center, a new class of van has been created that emphasizes lightweight construction, independence, travel experience and design. The vehicle celebrated its world premiere at the Caravan Salon in Düsseldorf, Germany, at the end of August.

“Hymer is synonymous with premium quality, innovation and a sense of discovery. The VisionVenture developed in tandem with BASF perfectly captures these values. It already promises to give our customers an entirely new sense of freedom,” said Christian Bauer, managing director of Hymer.

More than 20 high-performance plastics and a new painting technology from BASF are used in the concept camper and impress with a huge range of properties. BASF and Hymer use various lightweight materials and processes in the interior and exterior, providing comfort while also making the vehicle more robust. The VisionVenture also offers new solutions for energy management, thermal insulation and electrical components, a tailored package of measures for preventing noises and vibrations, and more than 100 3D-printed components.

“Our products give the designers unprecedented new options and functionalities for the VisionVenture,” said Martin Jung, head of Performance Materials at BASF. “The end result demonstrates the full diversity of our material competence – from inspiration to finished product.”

Other VisionVenture innovations include:

- The VisionVenture’s self-inflating pop-top roof inflates in less than 60 seconds, creating more living space. BASF’s Elastollan coating on the roof creates an outer wall that is resistant to water as well as wind.

- The cushions and mattresses in the VisionVenture feature the temperature-regulating effect of BASF’s Elastocoat C Spray Gel.

- A key contributor to the van’s cozy feel is Haptex, BASF’s polyurethane system for imitation leather, which spans the entire interior. This material feels soft and is available in a range of colors and textures. It is also extremely easy to clean and does not contain organic solvents.

- By combining plastics with natural materials such as hemp and slate to produce cupboard doors and kitchen fronts, the concept van has no need for heavy alternatives like wood or chipboard.

- For functional reasons, camper-vans are usually cream or white to avoid overheating during the summer. The gray-green VisionVenture proves that personal choice can also apply to the paintwork – thanks to BASF’s Chromacool temperature-management technology. Chromacool is available in a wide variety of colors. It reflects the sun’s infrared light, thus reducing the build-up of heat in the vehicle body. This passive temperature management means that heating of the vehicle’s surface is reduced by up to 68°F, with the inside temperature dropping by as much as 39°F. Less energy is needed for air conditioning, which helps to reduce fuel consumption, or to increase the range of electric vehicles.

- BASF’s Infinergy, primarily associated with the Energy Boost running shoe from adidas, appears in the steps and the bed frame and gives pressure point relief. As a connection module, it holds the slats in the slatted base together, resulting in an individually adjustable mattress base on account of its high material resilience.

- The two companies have also developed a customized NVH (noise, vibration, harshness) package to reduce vibrations and block noise in the interior, drive or chassis.