eMpulse Test Systems Supplies Load Frame to JRi Shocks

The advanced system allows customers to see damper testing firsthand to better understand product behavior before going to track or field testing…

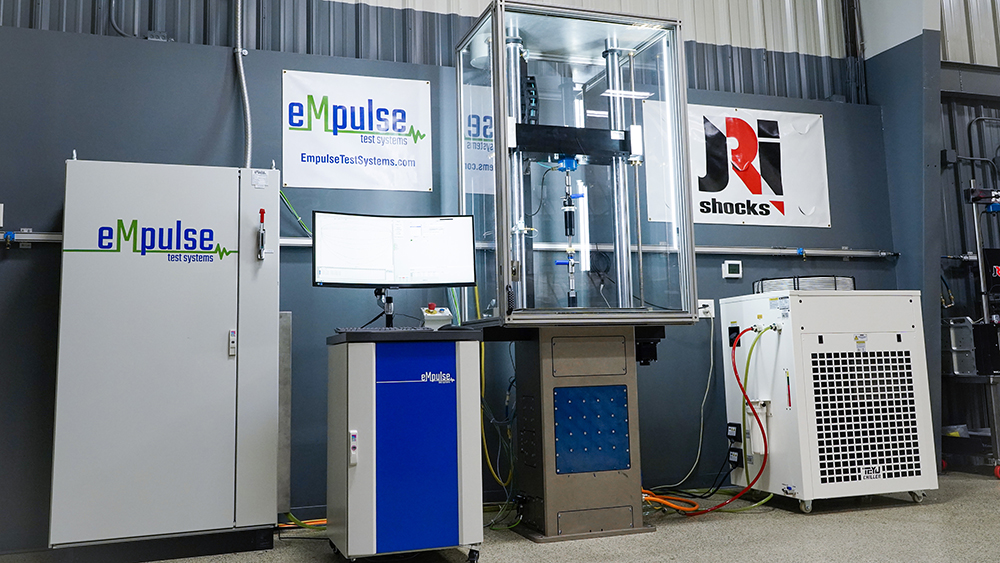

eMpulse Test Systems, a provider of high-performance servoelectric test solutions, has supplied a load frame to JRi Shocks for use in its damper development and evaluation programs. The system is now operational at JRi’s facility and will also support customer visits, demonstrations and product showcases, company officials stated in a press release.

The load frame features servoelectric actuation technology designed for precise force and displacement control, low noise and high repeatability, making it well-suited for damper performance validation, durability assessments and component characterization, the company said. By integrating the load frame into customer-facing demonstrations, JRi can offer a deeper look at how its products perform under controlled, real-world loading conditions.

“JRi is a respected name in high-performance suspension systems,” said Doug Boals, CTO, eMpulse Test Systems. “We’re proud to support their engineering and customer engagement efforts with a system that delivers precision, fidelity and reliable data.”

“Having a modern load frame in-house allows us to validate damper behavior under controlled conditions and showcase that performance directly to our customers,” said Jeff Ryan, president of JRi Shocks. “It gives us another tool to demonstrate the engineering behind our products and support data-driven development. The eMpulse machine brings the most advanced damper testing technology that I’ve witnessed in my 48 years solely working in this industry.”

In-House Damper Testing Allows JRi Shocks to Better Demonstrate Product Behavior

Located in Mooresville, North Carolina, JRi Shocks designs and manufactures advanced shock absorber systems for racing, off-road and performance applications. The demo installation provides an opportunity for its customers to see damper testing firsthand and better understand product behavior before going to track or field testing.

eMpulse Test Systems says the installation reflects its ongoing commitment to supporting industry partners with clean, efficient and high-accuracy test platforms. Leveraging servoelectric technology eliminates hydraulic fluids, reduces maintenance and provides tighter control of load, displacement and velocity profiles.