The article originally appeared in the March 2023 issue of THE SHOP magazine.

Performance fuel pumps and systems are a vital part of today’s high-horsepower engine builds. Whether on the street or at the track, drivers expect the fuel they need when they need it to get them where they’re going.

These days that fuel isn’t always gasoline, either, as diesel, ethanol and even methanol applications are on the rise.

Becoming a fuel pump and systems expert can help shops build trust and repeat business as customers chase power numbers and performance goals. To help you get there, fuel system insiders have a steady flow of information to share.

MAKING MORE POWER

Much of the innovation driving the performance fuel pump market comes from the need for more speed.

“Customers want higher-power and more-transparent fuel systems,” says Krista Lamb, director, products and customer experience for DeatschWerks. “This is pushing us to develop fuel components that work with the OE return-less and PWM-controlled systems to support 1,000-plus-hp street cars with relatively stock fuel systems that are daily-drivable.”

Drivers also want more fuel flexibility from their fuel pumps for a wider range of applications, states Bryan McTaggart, technical writer for Holley.

“Some combinations, like dual-fuel systems, weren’t as prevalent as they are now,” he says, “and enthusiasts have opened up to a broader range of fuels, especially ethanol-blended fuels, as E85/E90 will allow an engine to run cooler.”

Top builders will anticipate new uses down the road.

“A customer who is buying a fuel pump today for a carbureted application might also be looking at an EFI conversion in the future, or might consider moving to a different fuel type later on,” says McTaggart.

Some of the power numbers are staggering, reveals Phillip VanBuskirk, national sales manager for Aeromotive.

“Ten years ago, a 1,000-hp street car was crazy. Now that number has doubled, and 1,500- to 2,000-hp street cars are everywhere,” he says. “Many have turned to ethanol or methanol fuels and require more volume to support the big horsepower.”

High-volume pumps are a must for such applications.

“Mechanical pumps can support from 500 to 10,000-plus hp,” VanBuskirk continues. “With options of cam, belt or cable drive, mounting locations are almost endless. Cable-driven pumps at the back of the car have become very popular for racers who need large-capacity fuel cells in the rear of the car. And when a mechanical pump just won’t work, we offer up to 10 gpm with the brushless gear pumps.”

New vehicle designs are also pushing product innovation.

“Now that most diesel engines use common rail fuel injection systems, it has become more important than ever to provide superior filtration over the OEM filtration system, as even the smallest contaminates can be damaging,” says Josh Thornton, who does research and development for FASS Diesel Fuel Systems.

ANSWERING THE CALL

Selling and installing performance fuel pumps gives shops the upper hand when a customer comes in looking for a complete fuel system upgrade, Lamb explains.

“Fueling components aren’t pretty or flashy, like a new turbo or supercharger. The fuel system is often overlooked during the upgrade process,” she says. “Not understanding that oversight until the car is already strapped to the dyno and going through the tuning process when it runs out of fuel can be costly. Having fueling components on-hand and the knowledge of how to use them will allow shops to take care of their customers’ needs promptly.”

Manufacturers look to help shops by simplifying installations, McTaggart notes.

“Our 12-170 (in-line electric fuel pump) is designed to work easily with -8AN and -6AN fittings, which allows for an easy-to-design answer when creating a fuel system,” he says. “For most customers, the fuel system may not be as sexy of a project compared to paint or interior work, but they are willing to spend money on quality, durability and function.”

Successful projects can also lead to repeat sales, according to Thornton.

“Installing a FASS Titanium Signature Series not only benefits the truck it is installed on, but the shop can also benefit from residual fuel filter sales, FASS fuel heater sales and other add-ons,” he says.

Creating packages can mean add-on sales while ensuring the system functions properly.

“The less the customer has to be concerned about their fuel system, the better,” McTaggart says.

Helping drivers set up their fuel systems correctly in the beginning pays off in the long run.

“There are so many parts that go into a build and when the fuel system isn’t correct it can cause all kinds of issues later on,” warns VanBuskirk. “Selling and installing the fuel system gives you the confidence when it comes time to tune the car—it’s the last thing you are going to have to worry about.”

DRIVING THE MARKET

Performance fuel pumps and related components continue to be of particular interest to drag racing competitors.

“The rise in popularity of drag-and-drive events such as Drag Week and Sick Week brings with it the demand for consistent and reliable fuel delivery. DeatschWerks continues to drive fuel pump and supporting system component development to meet the demands of each motorsport,” says Lamb, citing as an example a 1995 Ford Mustang build with a DeatschWerks fuel system specifically for Drag Week.

“During Drag Week 2022 they hit their goal of running 5.50s in the 1/8-mile (8.50 in the 1/4-mile). The car runs and drives around on the streets on 93-octane pump gas in 100-degree heat and never gets over 180 degrees, and the passes they made had about 30 minutes between them in 95-degree heat with zero issues,” she recalls. “This customer shared that ‘the fuel system is rock solid.’”

Holley recently assisted freelance contributor Scotty Lachenauer with his 1965 Plymouth Barracuda. McTaggart explains how the partnership shows the versatility of today’s components.

“His A-body is powered by a Chrysler LA 360 that is breathed on with a Paxton centrifugal supercharger,” he says. “This is the kind of project that could have used our 12-170 pump regardless of how the engine was finished. Ultimately, the blown Barracuda received a Sniper Stealth 4150 throttle body and a HyperSpark ignition, but this fuel pump would’ve worked even if the car had stayed with a traditional four-barrel carburetor. There’s also plenty of room for power improvement before the fuel system needs to be reassessed.”

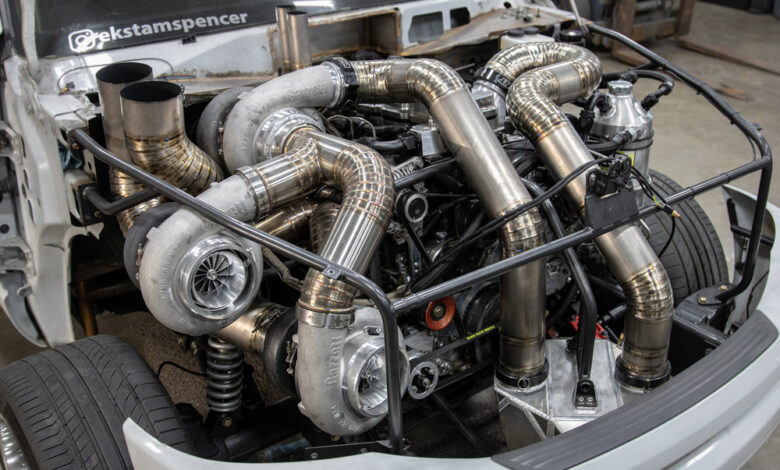

Spencer Ekstam is currently building several high-horsepower diesel trucks ranging from 1,500 to 3,000 hp, all fueled by a single FASS Fuel System, Thornton reveals.

“We have also worked with several Class 8 truck fleets to improve their bottom lines, ranging from decreased fuel consumption to prolonging the life of fuel injectors,” he adds.

As far as overall trends, Aeromotive’s VanBuskirk sees mechanical fuel pumps making their way into nearly every form of performance.

“We work with partners that use them in monster trucks, Sprint cars, NASCAR, standing mile, no-prep, drag-and-drive, WaveRunners, motorcycles and anything else you can race.”