Serving the Demand for High-End Automotive Mil-Spec Wiring

Jack Nickerson & JAX Motorsports are wired for success, making connections for top builds…

This article originally appeared in the August 2025 issue of THE SHOP magazine.

Mil-Spec. What on earth is Mil-Spec? Turns out, it’s an abbreviation of “military specification” and, in our automotive world, it describes electrical wiring done to military specifications using military-grade components.

To get a better understanding of this new wiring trend in the custom car, hot rod and off-road worlds, I sat down with Jack Nickerson of JAX Motorsports in Upland, California. Born in 1973, Nickerson is one of those rare California natives. His dad was not exactly a car builder, “but he would buy salvage cars, wrecks if you like, and restore them.”

Jack Nickerson didn’t really have a career path, but the father of one of his high school friends owned a boat shop.

“So, in 1991, I went to work there servicing boats,” Nickerson recalls. “I stuck at that until 1995, when I got tired of working on mom-and-pop boats and went to work at GT Performance in Montclair. GT was big into high-performance, building hot ski boats and offshore race boats. It was a busy shop, and I really enjoyed the work.”

He enhanced his real-world experience with a few auto shop and electrical classes at a local city college, and he and his dad also tackled a Camaro project at home.

“In 2000, I decided to get out of the boat business and went to work for Fred’s Custom Wiring and Auto Works in Ontario, California,” Nickerson says. “Fred Ingle has a solid reputation and has collaborated with many builders including Chip Foose. His work has been featured in a number of magazines. I quit Fred’s but went back over a period of 10 years.”

In 2015, Nickerson decided to get serious, rent a shop in Upland and open JAX Motorsports.

“It was totally scary, but in the past 10 years I have never had a day when I didn’t have work and it just seems to get busier,” he reports. “Obviously, I’m in the thick of the California car culture and there are lots of customs, hot rods, off-road vehicles and trucks being built, many with significant budgets that allow for the level of Mil-Spec I specialize in. Also, for many years, Southern California was the epicenter of the aerospace industry as well as the motorsports industry and consequently the infrastructure was there for the taking.”

FROM A TO B

JAX doesn’t strictly specialize in just Mil-Spec projects.

“I’ll tackle pretty much any wiring job, but (Mil-Spec) is a growing trend and to explain it in its simplest terms it is wiring to military specifications using military-grade components,” Nickerson says. “When I first got into this, the components were readily available here in Southern California from ProwireUSA.com, which was located in San Diego. However, they have now moved to Queen Creek, Arizona, but the service remains the same and I can get anything overnight.”

Enthusiasts seem to love the precision Mil-Spec delivers, but it does come at a price.

“For example, Deutsch Autosport connectors, which are the top-of-the-line connector for high-end racing where size, weight and reliability are of the utmost concern, cost over $200 each. I use those, for example, for connecting the engine harness to the cab or cockpit,” he reports.

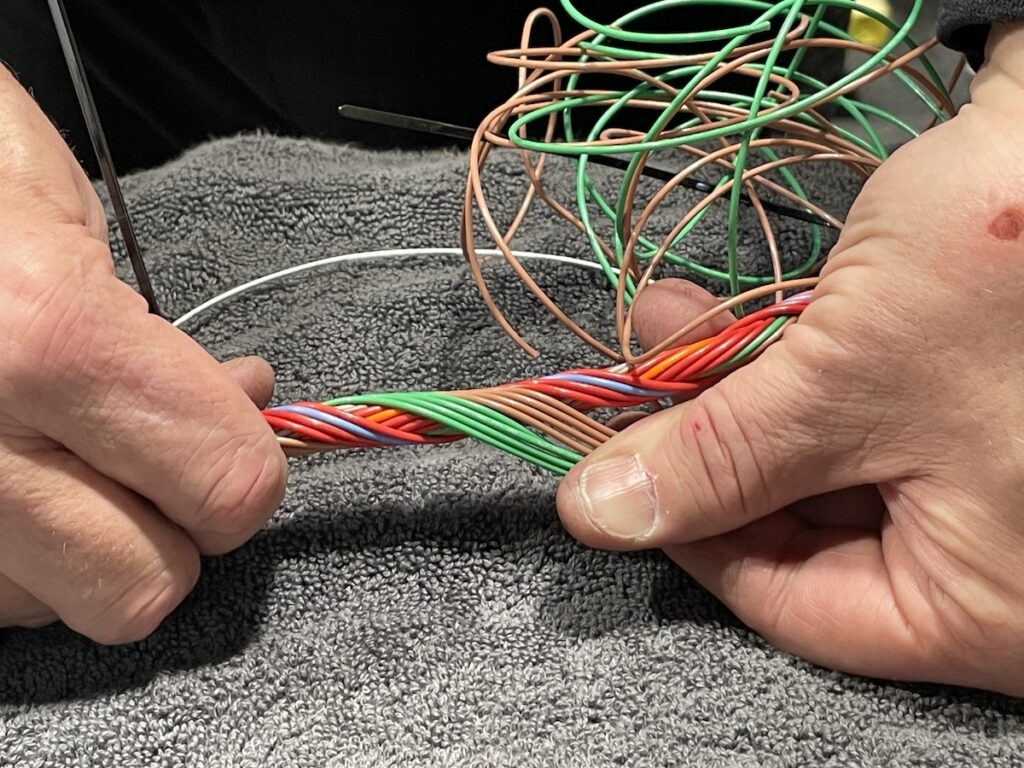

The wire itself is also expensive. A 250-foot roll of regular 18 SWG (Standard Wire Gauge) wire is around $30, whereas a similar 250-foot roll of Tefzel aircraft wire is priced at $104—nearly four times as expensive.

Other Mil-Spec materials such as Raychem shrink wraps are equally pricey because they are resistant to aviation and diesel fuels, hydraulic fluids and lubricating oils. They are available for high-performance applications in different colors and even clear (to protect labels) if builders need to see the colors of the wire. And, perhaps most importantly, some have a 4:1 shrink ratio to get things small and tight (most shrink wrap has about a 2:1 shrink ratio).

“Beyond the cost of the materials, the process of actually wiring the car is time-consuming because it has to be right,” he adds. “A normal wiring job from scratch on, say, a 1955-57 Chevy or a run-of-the-mill hot rod will take about 100 hours. Wire it to Mil-Spec and the time taken can easily jump to 300 hours and sometimes longer if it’s a show car, such as Larry Jacinto’s 1941 Willys pickup that had to be perfect.”

SHOWCASING QUALITY

Mil-Spec wiring isn’t for everybody. But it is for builds that showcase quality.

“For the 2024 SEMA Show, I wired Rob Lindsay’s ’49 Willys Ultra4 luxury pre-runner truck built by RJ Fabrication and powered by a Whipple-supercharged LS3,” Nickerson recounts. “That was a very intense, four-year build that took several hundred hours to wire. The stunning truck won the 2024 Battle of the Builders 4-Wheel Drive & Off-Road segment. I also wired RJ Gottlieb’s well-known ‘Big Red’ Camaro.”

The work at JAX Motorsports is shared among hot rods, customs and off-road-type racing vehicles where reliability is paramount.

“However, the custom work is steadily growing as the standard of builds increases,” he says. “Probably 50% of my builds are now Mil-Spec.”

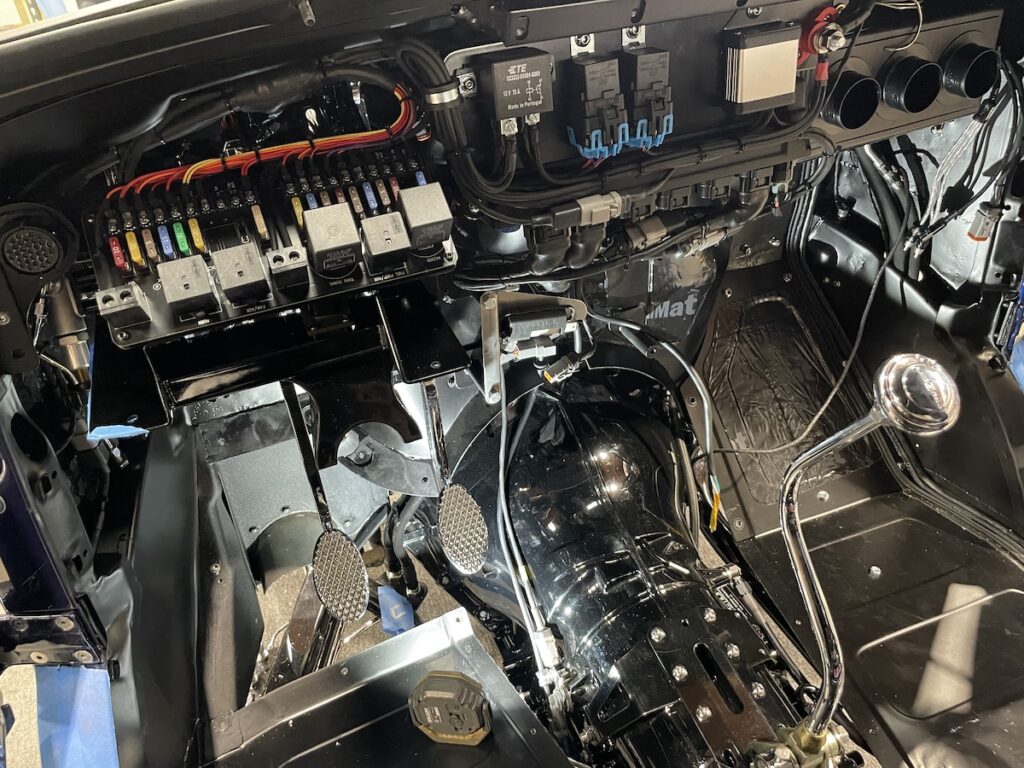

JAX begins each wiring job by looking over and measuring the vehicle to get an idea of the layout and complexity.

“I always do that before I ever cut a wire,” Nickerson says. “Next, I make a ‘pin-out’ spread sheet for each connector indicating where each pin goes to. I don’t really make a wiring diagram, because if you understand how it all works together then you don’t really need one—you just need to know where each wire goes. The color is irrelevant. Many airplanes have single-color harnesses because it doesn’t matter to them what color the wire is.”

He’ll start with the engine harness (ECU) so that, if necessary, the engine can go to the dyno while he’s doing the rest of the wiring.

“This way, the engine harness is proven early on in the game and typically I make a jumper harness that connects my engine harness to the dyno shop harness. While the engine is out being dynoed, I work on the rest of the vehicle and usually work on the front and rear harnesses before diving into the inside where all the tricky work is.”

For someone with Nickerson’s skill and experience the rest is fairly straightforward, “but sometimes integrating modern ECUs such as a Holley EFI or Dakota Digital instrument clusters into old factory equipment can be difficult, for example, on a typical pre-runner truck. However, there are few problems if all the components are modern and you’re not mixing old with new.”

The idea is for the finished product to be 100% reliable and 100% gorgeous.

“As most of us say in the industry, it’s time and materials and getting it to work right, but equally important is getting it to look right,” he says. “That’s my goal.”