This article originally appeared in the November 2023 issue of THE SHOP magazine.

Many industry folks call the Pro-Touring market the gift that keeps on giving. That’s because this popular niche includes so many aspects and genres, not to mention fans from all walks of life.

Pro-Touring covers cars and trucks from all eras—everything from common classics to obscure marques. Whether a typical barn find or a dust-covered “heirloom” that’s sat covered in a garage for decades, modern technology is breathing new life into these old favorites.

From the shop’s perspective, restomodding can be whatever your customer wants it to be, from mild street upgrades to a high-end custom creation to a full-on race machine.

With the fall trade show season upon us, now is a great time to see what’s new and what’s hot in Pro-Touring. Suppliers highlight some common misconceptions and ways to increase sales—proving these older vehicles still have more to give.

ADVANCED DEGREES

When Pro-Touring really took off about 25 years ago, the cars were an obvious blend of old meets new. Years of innovation, however, mean that nowadays it’s difficult to tell where the original parts leave off and the new ones take over.

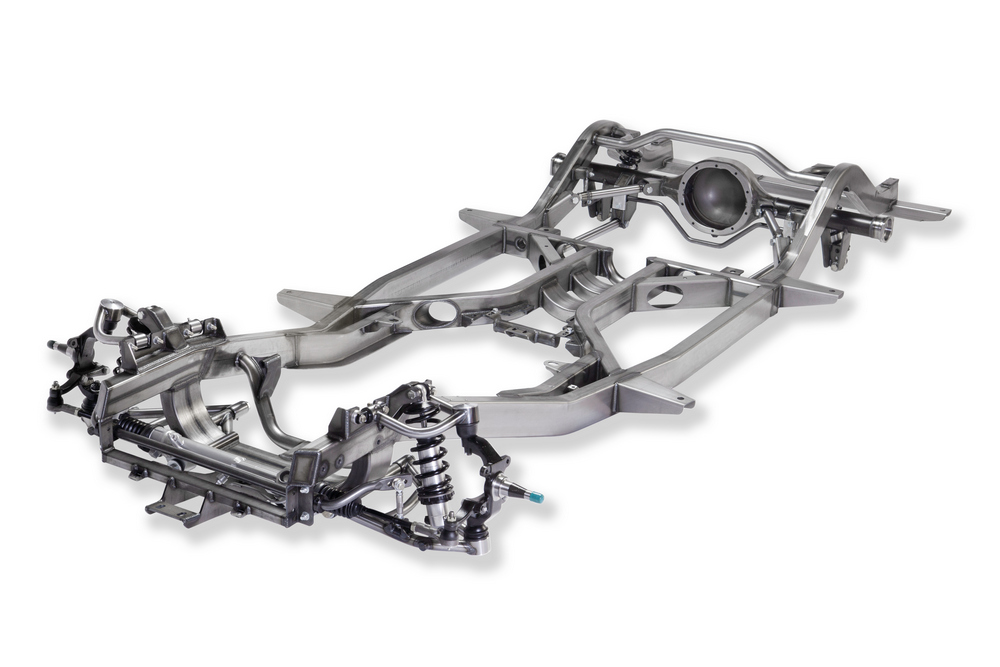

“The Pro-Touring market has become much more advanced,” observes Trever Cornwell, president of IDIDIT. “A decade ago, people were bolting on upgrades. Now it’s very common for builds to include a complete aftermarket chassis with completely re-engineered suspension geometry. The size of the market has grown significantly.”

Often basic on the outside, dig deeper and you’ll find advanced components to rival any new vehicle.

“Pro-Touring continues to evolve with additional products being available, many of which have improved technology,” says Tim Sayers, muffler development manager at Borla Performance Industries.

Any discussion of restomods, as they are sometimes called, obviously must include improved performance—and the time it takes to get there.

“The market has changed in terms of build quality and build speed,” notes Matthew Jones, president of Art Morrison Inc. “Lots and lots of high-end cars are being built that showcase immense talent in the industry. Also, cars are being built faster than before. As shops get a backlog of customers, they realize that they need to be more efficient at building these vehicles—or take on easier projects.”

SPECIAL BLENDS

As the industry has grown, so have opinions regarding what works and why. Still, insiders agree there are some common pitfalls and roadblocks to avoid.

For instance, Jones believes that too many shops simply open a catalog and choose parts without knowing if they are compatible.

“There are many kits out there for suspensions and such, but mixing and matching parts doesn’t always work well, and definitely doesn’t compare to a completely engineered package,” he says. “In the end, if the car doesn’t ride well or is darty on the freeway, some will just shrug their shoulders and say, ‘It’s an old car, that’s the way it is.’ But a complete package should solve all drivability issues.”

Another build strategy to avoid, says Sayers, is sticking solely with what’s worked before.

“A common misconception is that what was popular in the past is currently popular,” he explains.

One nice thing about Pro-Touring’s staying power, however, is that the vehicles are now celebrated and appreciated almost universally.

“In the past, they (Pro-Touring cars) weren’t considered a hot rod,” says Cornwell. “I think that’s changed over the past few years.”

MOVING FORWARD

There’s seems to be no slowing the interest in Pro-Touring, including for shops looking to turn out as many quality builds as quickly as possible.

“It’s all about speed,” says Jones from Art Morrison, who recommends investing in products designed for the market. “Items that don’t require painting or pre-assembly will decrease build times and people are willing to pay for them.”

Borla’s Sayers reminds shop owners to pay attention to history.

“Stay current with how the market has evolved. Have an in-depth conversation with the customer to understand their expectations prior to taking on the job,” he recommends. “Then, check in with the customer multiple times during the build to make sure what they want hasn’t changed. The end result will be a satisfied customer who will promote your shop.”

Finally, IDIDIT’s Cornwell reminds builders that it’s called “Pro-Touring” and not “restoring” for a reason.

“Don’t waste your time with factory components, especially steering,” he suggests. “They weren’t designed for the loads and stresses put on them in a Pro-Touring build that is driven hard or taken to the track. New and modern components increase drivability and safety. We sell virtually all of the components for a steering system to create a more enjoyable driving experience with more modern safety considerations incorporated into them.”