Makerspaces: A Space for Business

Auto pros love these membership-based DIY workshops & fabrication facilities

This article originally appeared in the July 2023 issue of THE SHOP magazine.

There’s no doubt the industry desperately needs tradespeople of all stripes—everyone from CNC machinists to welders. We skipped a whole generation as we sent everybody off to college and university to get a degree, and that decision is now coming back to haunt us.

Not that there’s anything wrong with getting a degree—there absolutely isn’t—but we still need competent people to make and mend things.

Obviously, there are trade schools all over the U.S., but prior to the pandemic there were a number of so-called “makerspaces” that were very effective incubators for budding engineers and entrepreneurs.

Makerspaces, of which the now defunct TechShop was perhaps the poster child with a much publicized visit from former President Barak Obama, are membership-based, DIY workshops and fabrication facilities. They offer the trained and untrained a cost-effective co-op facility in which to learn a trade or even start and run a business.

It’s a great concept, but a business model that is very difficult to sustain.

FIND YOUR SPACE

In a previous life I was actively involved in education, and I visited a lot of makerspaces on the West Coast and in the Detroit region. Most are now gone, but ex-Mazda designer Truman Pollard introduced me to Urban Workshop (UW) in Costa Mesa, California, where he has been a youth program instructor since 2019.

Founded in 2014 by owner-operator Steve Trindade, Urban Workshop is housed in a 28,000-square-foot facility with easy freeway access in Orange County.

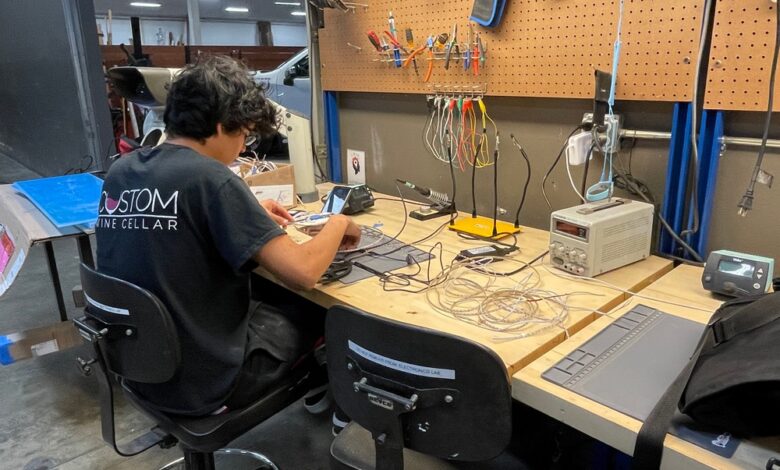

With a comprehensive range of tools and equipment—more than $1 million worth, including Solidworks software, 3D printers and a CNC mill—UW enables members to realize projects in a clean, safe environment where there is always professional assistance available to help get the job done. Members can run a business out of the facility, keeping startup costs to a minimum.

“With more than 300 members, we have several that operate small businesses from here, ranging from people making furniture to people restoring cars and converting vans,” Trindade says.

Individual memberships start at $199 per month (annual agreement), offering full access to the facility, computers, meeting spaces, tools and equipment, on-site materials, Wi-Fi, experienced staff members, storage, etc. For a startup business, that’s very reasonable.

You can also purchase month-to-month memberships for $249 per month. If you had a short-term project, say, three to six months, that program would be ideal. Incidentally, students and military members get a month-to-month price of $195, and there are family and lifetime membership programs viewable on the website (urbanworkshop.net).

As the website points out, the benefits of using a makerspace to kick-start a business are numerous—there are no long-term commitments or leases, no deposits, no personal guarantees, no insurance requirements, no capital equipment expenses and no tenant improvements (TIs) to make. You can start a side hack, using somebody else’s space and equipment, and see if it works before quitting your day job.

And there’s a track record. Some of the businesses that got their start at UW include vehicle upfitter Aiden James Customs, robot company Brikeda, Herst Coffee Roasters and SZK Metals that specializes in architectural metal fabrication.

TIME IN THE GARAGE

Along with the “crafty” areas where people are making furniture, performing 3D printing and assembling electronics, there’s an area of UW dedicated to automotive, including Instavan and American Corvair Service operated by Barry Sparks,

“I have a close affinity to the auto side,” Trindade notes. “Until I started Urban Workshop, I was heavily involved with racing as president and CEO of Automotive Technology Group Inc., and after that as owner/COO/CFO and technical director of Socii Racing LLC, doing business as Truspeed Autosport. When the racing came to an end, I started Urban and in less than 10 months turned it into the third largest DIY workshop and makerspace in North America.”

To be successful, most makerspaces require four revenue streams: membership, onsite storage, adult educational classes (for which you don’t have to be a member) and youth programs.

“I was initially reluctant to embrace youth programs,” Trindade admits. “Having children around equipment can be challenging, but youth programs now account for 30% of our business. And, I have to say, it’s very rewarding to see children ages 10-16 enter the program with absolutely no knowledge or experience and emerge as enthusiastic and competent budding craftspeople.”

UW’s goal is to help students become curious about how the world works while introducing them to modern and traditional tools and techniques.

“We believe that everyone should be self-sufficient and have the skills and confidence to be able to fix and invent things,” says Trindade. “This leads to young people who know how to think on their feet, solve real-world problems, are aware of the tools available to them and know how to use those tools.”

ROOM TO GROW

Urban Workshop surviving the pandemic is a testament to the management skills of Trindade and his team. So, now that the acute shortage of technicians of all kinds is obvious, what does the future hold?

Growing the makerspace community, for one.

“We know from experience that starting, operating and maintaining a profitable makerspace is expensive and tough,” Trindade says. “Consequently, we offer a Makerspace Blueprint licensing program for individuals and institutions that wish to start, operate or scale a makerspace. By implementing our blueprint, somebody can shortcut the time and investment that we made to become sustainable, even in the toughest economy.”

It starts with initiating the four revenue streams necessary for success.

“You can use the proven documents we developed to quickly establish both adult and youth course curriculums,” he says. “You can use the time and money saved to develop impactful programs, and our licensing program provides valuable ongoing support by our experienced team to guide you through the process.”

Kre8Now Makerspace in Lexington, Kentucky, recently took UW up on its offer.

“We were able to double their monthly revenue, increase profitability, add a new revenue stream, rework the existing adult education programs and hire two additional staff members in just the first six weeks,” Trindade reveals.

During my tenure as an educator, it was obvious that there were a lot of students who were not necessarily destined for an academic career, and that’s perfectly OK—it’s not for everybody. Besides, we have a lot of lawyers.

What we don’t have, especially in the auto industry, are skilled workers. Practically every shop I know is desperate to find fabricators, body shapers, welders, painters and technicians.

If makerspaces provide an environment where people can get started on those skills and help build our workforce, then I believe we should do what we can to help support them.