- KPI – November 2025: The Brief

- KPI – November 2025: State of Business – Automotive Industry

- KPI – November 2025: State of the Economy

- KPI – November 2025: Consumer Trends

- KPI – November 2025: Recent Vehicle Recalls

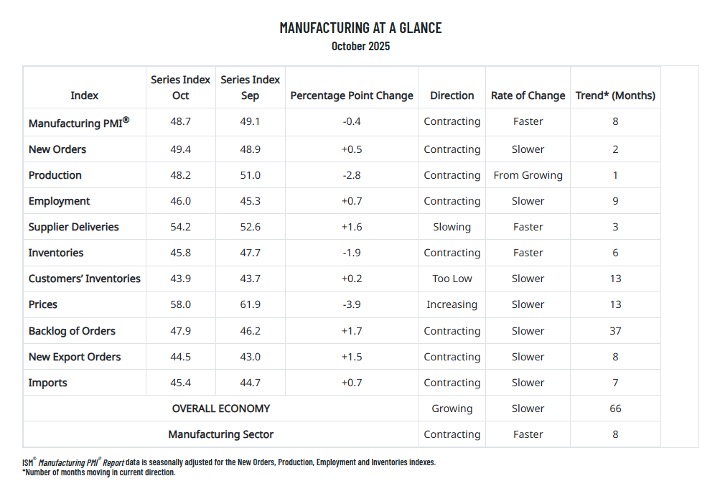

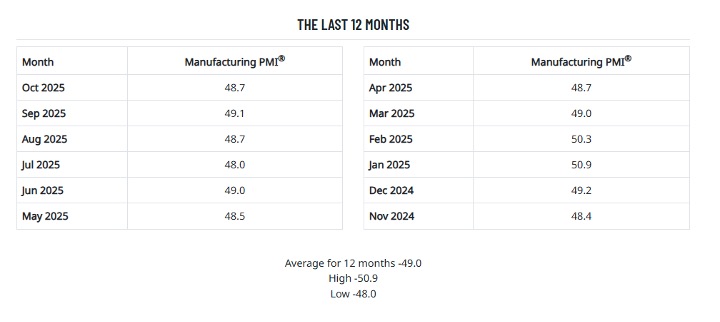

Economic activity in the manufacturing sector contracted in October for the eighth consecutive month, following a two-month expansion preceded by 26 straight months of contraction, say the nation’s supply executives in the latest ISM Manufacturing PMI Report. The Manufacturing PMI registered 48.7% in October, a 0.4% decrease compared to the reading of 49.1% recorded in September.

“In October, U.S. manufacturing activity contracted at a faster rate, with contractions in production and inventories leading to the 0.4-percentage point decrease of the Manufacturing PMI. A chain reaction of one-month index improvements started with New Orders in August and flowed to Production in September. In October, it manifested in a 1.7-percentage point increase in the Backlog of Orders Index. These short gains have not appeared to translate into sustained growth for the sector, a reflection of continuing economic uncertainty,” says Susan Spence, MBA, chair of the Institute for Supply Management (ISM) Manufacturing Business Survey Committee.

Data shows 58% of the sector’s gross domestic product (GDP) contracted in October, down from 67% in September. However, the percentage of GDP in strong contraction (registering a composite PMI of 45% or lower) is at 41%, up 13% from September.

“The share of sector GDP with a PMI at or below 45% is a good metric to gauge overall manufacturing weakness. Of the six largest manufacturing industries, only two (Food, Beverage & Tobacco Products and Transportation Equipment) expanded in October,” says Spence.

Important Takeaways, Courtesy of the Manufacturing ISM Report On Business:

- All of the four demand indicators (New Orders, New Export Orders, Backlog of Orders and Customers’ Inventories indexes) improved, although they are still in contraction territory. The Customers’ Inventories Index contracted at a slower rate. A “too low” status for the Customers’ Inventories Index is usually considered positive for future production.

- Regarding output, production deteriorated and employment contracted at a slower pace, as 67% of panelists indicated that managing head count is still the norm at their companies, as opposed to hiring.

- Inputs (defined as supplier deliveries, inventories, prices and imports) were mixed, with the Supplier Deliveries Index indicating slower deliveries, the Inventories Index contracting at a faster rate and the Prices Index continuing to indicate pricing increases but at a slower rate. The Imports Index contracted at a slower pace.

What Respondents Are Saying:

- “Business continues to remain difficult, as customers are cancelling and reducing orders due to uncertainty in the global economic environment and regarding the ever-changing tariff landscape.” [Chemical Products]

- “Decrease in domestic demand for finished products has resulted in slower manufacturing and an increase of raw material in inventory.” [Petroleum & Coal Products]

- “In general, business is really strained. Money is sitting tighter, and geopolitical changes add to the uncertainty/risk factor. Even medical fields are feeling the pressure.” [Miscellaneous Manufacturing]

- “Sales continue to underperform in our automotive OEM and industrial divisions. Our aerospace and automotive aftermarket are the only areas performing slightly above budget. This is the third month of lower-than-expected sales, and the remainder of the year outlook is not looking better. Sales are expected to be slightly less than in 2024.” [Fabricated Metal Products]

- “Tariffs continue to be a large impact to our business. The products we import are not readily manufactured in the U.S., so attempts to reshore have been unsuccessful. Overall, prices on all products have gone up, some significantly. We are trying to keep up with the wild fluctuations and pass along what costs we can to our customers.” [Machinery]

- “The commercial vehicle (CV) market remains depressed as customers continue to delay vehicle purchases. Uncertainty in price and transportation demand remains the center of attention. U.S. trade policy and reciprocal actions by China in the form of export controls on rare earths and semiconductors, as well as ocean freight carrier restrictions, have once again caused a lot of stress in supply lines. The CV industry is now bracing for the next round of tariffs focused on commercial vehicles, scheduled to begin on November 1.” [Transportation Equipment]

- “The tariff trade war has negatively impacted agricultural export markets, driving down demand and price. This negatively impacts farmer revenue and the likelihood of farmers investing in new equipment.” [Machinery]

- “The unpredictability of the tariff situation continues to cause havoc and uncertainty on future pricing/cost. But even with the tariffs, the cost to import in many cases is still more attractive than sourcing within the U.S. Challenges with tariffs on production equipment necessary for internal production makes it difficult to justify expansion of capacity.” [Computer & Electronic Products]

- “Volatility in some of our highly exposed commodity markets has tempered a bit, thanks to improved weather conditions and overall downward pressure on pricing. Tariffs continue to remain difficult to quantify, manage and deal with in general, since they continue to impact us day-to-day and our bottom line.” [Food, Beverage & Tobacco Products]

- “Wonder has turned to concern regarding how the tariff threats are affecting our business. Orders are down across most divisions, and we’ve lowered our financial expectations for 2025.” [Chemical Products]