Custom Builder Shop Class: Knowledge Is Power

Rodger Lee of Ironworks Speed & Kustom shares lessons in an academic setting...

Editor’s note: This article originally appeared in the January 2025 issue of THE SHOP magazine.

“We’re men in business, not businessmen,” proclaimed my old boss and mentor, Pete Chapouris of SO-CAL Speed Shop.

Chapouris was on the money because so many in the performance aftermarket, and especially on the hot rod end of it, have no formal business training—they got into it because they thought it might be a good use of their skills, might be profitable and might even be fun.

Chapouris was on the money because so many in the performance aftermarket, and especially on the hot rod end of it, have no formal business training—they got into it because they thought it might be a good use of their skills, might be profitable and might even be fun.

What they didn’t acknowledge was the need for accounting, HR or personal and time management skills to enable them to enjoy a successful business. There was no “Hot Rod U”—until now, that is.

JUMPING IN

In 2001, Rodger Lee started Ironworks Speed and Kustom (IS&K) in Bakersfield, California, and 20 years later he’s created a curriculum for his Business Development Class.

“I was a mechanic,” says Lee. “I got laid off or maybe fired from my job at a tractor repair shop and wondered, ‘What next?’ I was already renting a 700-square-foot hobby shop and thought, ‘Why not go into business for myself?’ That was 2001. I knew nothing, had no formal business education, but I was willing to fail—I didn’t want to fail, but I had nothing to lose. I soon moved into a slightly larger shop, with a bathroom and an employee, and I did everything I could to keep the doors open, from building lumber racks, painting trailers and working on customer cars—it was a steep learning curve.”

Lee was a self-confessed car guy devouring magazines and so-called reality TV shows to learn all he could.

“I was a nobody in a world populated by icons such as Chip Foose and Jesse James, but I had that dream of working on cars—not tractors. I’m 6-foot-6, you can’t miss me, but I knew I had to build a stand-out reputation for top-notch work. I’m always champing at the bit to know how things are done and how to do it better. I make quick decisions, but I strategize everything I do. I analyze the situation and make a decision.”

The turning point for IS&K came when Lee decided to rebuild his 1957 Chevy step side shop truck utilizing a tube chassis featuring his own suspension design and a Kinsler stack-injected LS2.

Debuting in 2009, the understated ’57 put IS&K on the map, garnering some 180 pages of magazine ink. It was a finalist for the 2009 Goodguys Truck of the Year. It also won a GM Design award at the SEMA Show and was a Mother’s Choice award in 2010.

“The ’57 showcased my build skills beyond anything I could imagine—it was a huge learning curve and IS&K began to attract customers with higher standards wanting turnkey builds. I have one customer that I have now built 14 cars for—that’s customer retention. Another I have done five or six for, and two other guys are on their third.”

This subtle shift in business meant that more fabrication work needed to be handled in-house rather than outsourced; therefore, he needed more talented fabricators and more equipment including a 3D printer and a CNC plasma table as well as the traditional shop equipment such as an English wheel that Lee built himself in the early days.

FINDING A BETTER WAY

Lee’s business approach is decidedly different from most hot rod shop owners I have interacted with, but as he says, he is constantly strategizing and exploring how he can do it better.

It’s that process that led to partnering with his friend Troy Gudgel of BBT Fabrications in Mahomet, Illinois, and the creation of the Ironworks Business Class.

“I wrote the curriculum,” Lee says, “and then sat on it for a long time because I didn’t feel qualified to teach it. But I knew there was a need—I had needed it—but there was nobody out there offering sound business advice. For example, it was eye-opening for me to realize that the quality of a car build in no way reflected the success of the business behind it. Builders can, and often do, turn out a show winner but make no profit.”

The course, which lasts two days, costs $3,500.

“I figured if they’re not willing to pay, they’re not ready to learn,” says Lee. “I priced the class so that if only one person showed up, I wouldn’t be upset. But in the review part at the end of the class everyone has said that it was worth every penny and more, which surprised and pleased me as I am not that well-spoken and sometimes have problems finishing my sentences.”

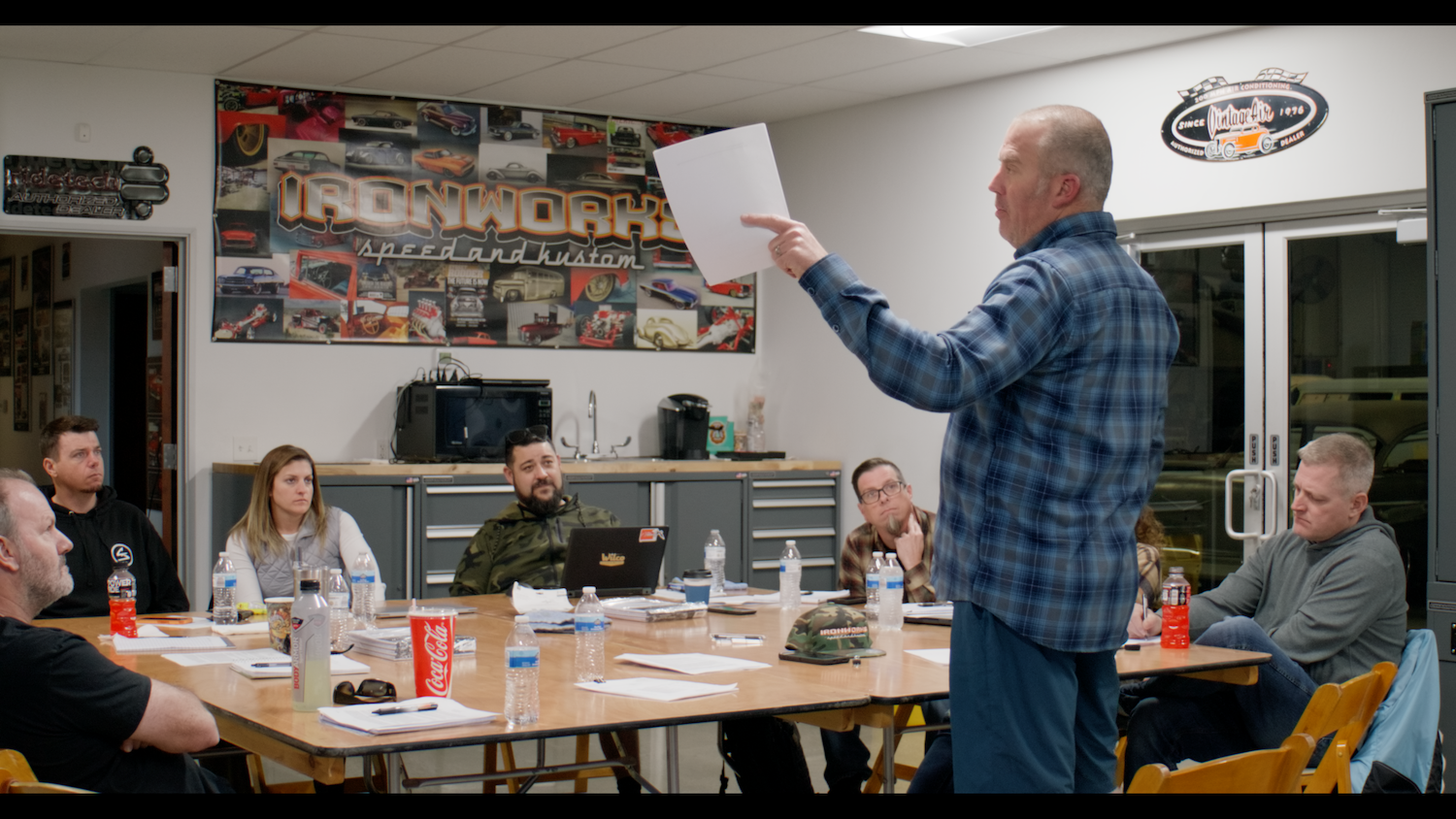

Classes start with a meet and greet for attendees the night before, followed by two solid days of immersive education that includes everything from an extensive shop tour to a full, in-depth deep dive into the entire shop process.

“We also leave the shop and go out to eat so that everybody gets to ride and talk with different attendees, not just those they sit next to during the class,” he explains.

The course starts with discussions of things a shop owner needs to consider early on, something Lee calls “selecting the lane the builder wants to be in—the kind of cars they want to build, the style, the build quality they aspire to, and the skill levels of their employees.”

Next is finding customers that fit that chosen lane and then keeping them and the shop owner on track.

“We talk about providing the customer the information they need to understand the build process, why it takes time and, most importantly, that building cars at this level is not a cut-and-dried, cookie-cutter process.”

TIME IS MONEY

Time and money are also discussed. For instance, for shop owners, the car build is their business but for the customer it is his or her hobby, so often they are going to want to hang around the shop and talk about their vehicle—it’s part of the process.

With today’s shop rates ranging between $100-$200 per hour, the daily shop bill for one person is obviously $800 to $1,000-plus. At times, a build will get so labor-intense that the daily bill can easily be $4,000 per day with five people on the car. Multiply that by five working days and a weekly bill can reach $20,000 or more, and that can go on for weeks.

Customers also forget that toward the end, when they think you are close to finishing, bills for chrome, upholstery and paint stack up prodigiously along with the labor. Therefore, both you as the builder and your customer need to know where the project is going, and the customer needs to be constantly updated through communications and photographs to keep everyone on the same page.

“Remember,” Lee says, “the customer is not a car builder. They might have been very successful in their chosen field, but they’re not as knowledgeable as you are in the arena of car building. That’s why they came to you, and you’ll want to meet and/or exceed their expectations with great customer service.”

The class also explains the disciplines builders need to adopt to make their shops more effective, efficient and profitable.

“Typically, with 10 or more attendees, the course also affords you the opportunity to discuss directly with and learn from other shop owners in a similar situation who might have conquered a problem you are encountering,” Lee notes. “Because of this interaction, the course tends to be as much a discussion as it is a directive.”

Another hot topic is pricing.

“One of the biggest problems shop owners face is being able to charge what they should. They tend to value their work according to their wallet and bill accordingly, rather than billing according to the customer’s wallet.”

Attendees may view the course cost as expensive, Lee admits, “but we think it offers extreme value for the money and all the classes we have held have returned A-plus responses from the attendees. I even had one attendee come work for me for a week to pay his tuition, but I’m not encouraging that.”

The classes are supported by companies who provide gift certificates, product or reduced buy-ins for attendees including BFGoodrich, Bowler Transmissions, BBT Fabrications, Forgeline Wheels, Jason Killmer of JK Automotive Detailing, Roadster Shop, Verified Fabrication, Vintage Air and Wilwood, affording attendees instant ROI.

Indeed, the industry has taken such note of Lee’s business class that he has been approached by trade associations and industry leaders about partnering, but he and Gudgel prefer to keep it in-house, at least for now.

“We enjoy building cars and so, for the time being, that’s where our focus remains,” Lee says.

The next class is scheduled for late February in Mahomet, Illinois. For information click here.