Mustang Advanced Engineering (MAE) is currently designing, developing and manufacturing made-to-order test stands for various electric vehicles (EVs), including drivetrains (electric motor, power supply and inverter) and electric axle testing projects.

MAE recently delivered a test stand to Proterra, a manufacturer of zero-emission heavy-duty EVs based in California, for research and development testing of Proterra’s electric drivetrains. The system MAE delivered included a 350 HP regenerative AC dynamometer, 350-700 VDC programmable battery simulator, a cooling circuit with chiller and digital controller, vibration measurement, data acquisition and MAE’s TestCell software package tailored to meet the customer’s unique needs.

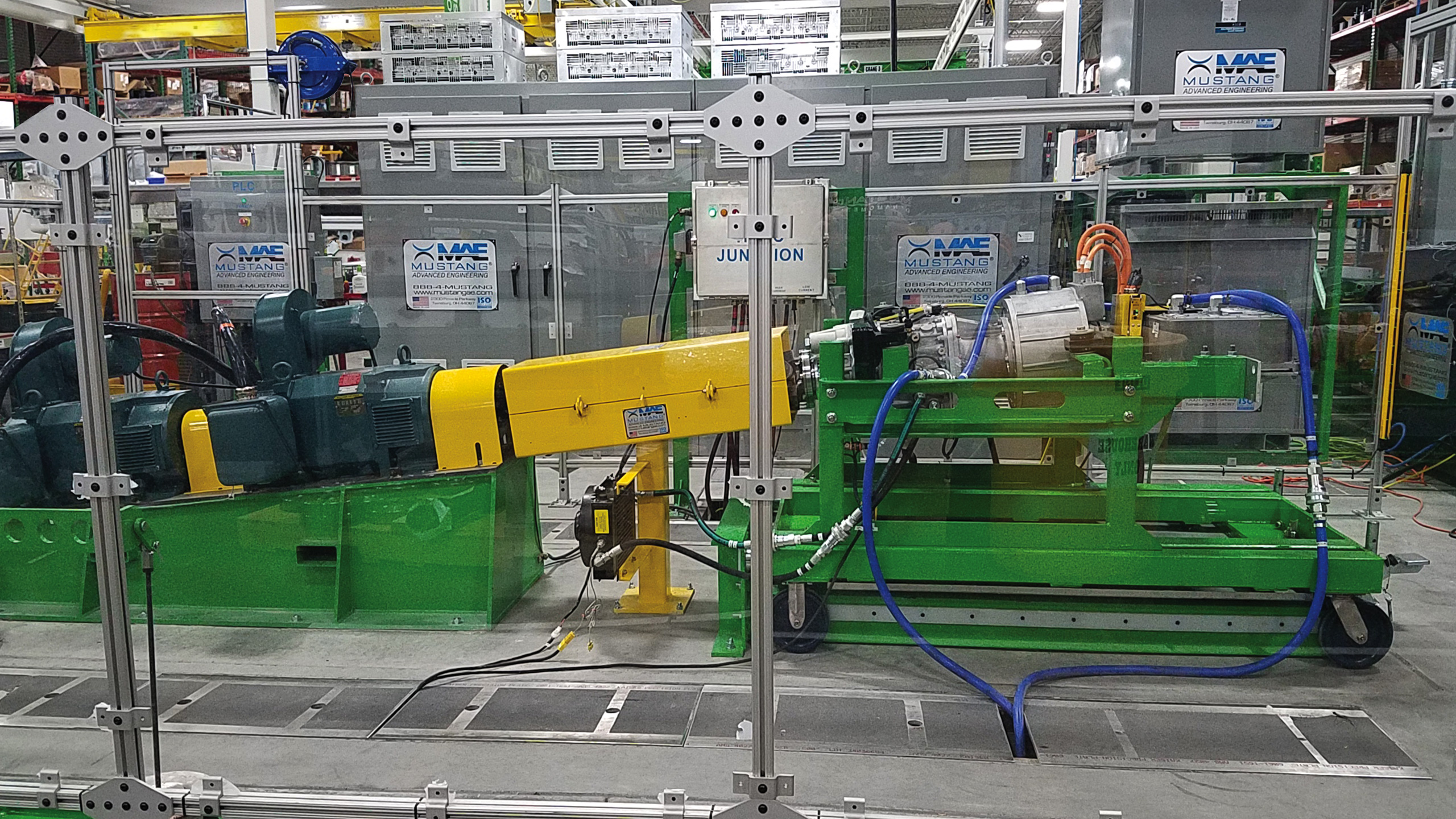

For Proterra’s South Carolina facility, MAE designed and built a test stand that tests their electrified power packs. These tests are under fully loaded conditions and every drivetrain is tested prior to being installed in the vehicle to ensure the most stringent quality standards are met prior to the product being delivered to Proterra’s customers, the company said. MAE provided the capability to flash the drivetrains with the appropriate firmware and test it under in-use conditions.

“MAE specializes in making test stands that are made to clients’ specific needs, and the Proterra drivetrain test stand demonstrates this expertise. There is no project that is too big or too small for the MAE team” said David Ganzhorn, V.P. sales.