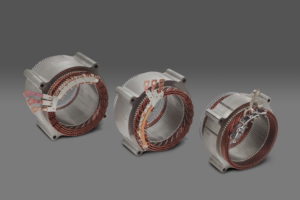

General Motors President Mark Reuss recently revealed GM’s group of three all-new motors that will power its Ultium-based EVs.

Designed by GM, the 180-kilowatt front-drive motor, 255-kW rear- and front-drive motor and 62-kW all-wheel drive assist motor are part of Ultium Drive. All three motors were calibrated in-house to ensure the highest level of performance in Ultium-based EVs, the company said. The motors were built as a scalable family, sharing design principles as well as similar tooling and manufacturing strategies.

“Twenty years of electric drive system development and more than 100 years of high-volume vehicle engineering are helping GM pivot quickly from conventional vehicles to EVs,” Reuss said at the 2021 Mackinac Policy Conference sponsored by the Detroit Regional Chamber. “Our vertical integration in this space, encompassing both hardware and software, helps give us control over our own destiny and a significant competitive advantage.”

The 180- and 255-kW units are permanent magnet motors designed with the aim of minimizing reliance on heavy rare earth materials while the 62-kW unit is an induction motor. All are expected to offer excellent torque and power density, enabling a wide spectrum of vehicle types, from performance cars to work trucks, the automaker said.

As many as three electric motors can be used in one EV – variations of the 2022 GMC HUMMER EV will feature three separate 255-kW motors, yielding a GM-estimated output of 1,000 horsepower1.

GM engineers have also developed the software for Ultium Drive’s motor controllers, which is key to serving the propulsion needs of various vehicle types with a minimal set of components, designers said. These engineers, based at GM’s Global Technical Center in Warren, Michigan, Global Propulsion Systems in Pontiac, Michigan; and Milford Proving Ground, are part of the nearly 11,000 GM product development team members currently working in software development.

The team used computer-assisted and virtual engineering to move quickly, safely and in a cost-effective manner while also improving vehicle controls. Artificial intelligence and machine learning helped determine the most efficient ways to distribute torque in three-motor systems, like in the GMC HUMMER EV, allowing the extremely off-road capable vehicle to also drive comfortably on surface streets.

The software behind GM’s EV motors can be reused in many applications, providing fast go-to-market times as well as the foundation for future EV expansion, as these motors are versatile enough to provide the power needs for a complete lineup of vehicles, Reuss said.

GM also designed the software of key power electronics components – like the power inverter module or inverter, which converts DC voltage from the battery to AC voltage to power the motor.

The inverter and other power electronics, like the accessory power module and onboard charging module, reside outside of the drive units on GM’s current EVs. In Ultium-based vehicles, they will be integrated directly into Ultium Drive units, reducing cost and manufacturing complexity.

Some power electronics will have as much as 50 percent less mass and volume than today’s GM equivalents, with as much as 25 percent more capability.

GM’s all-new EV motors and integrated power electronics, contained within its Ultium Drive units, will debut on the 2022 GMC HUMMER EV later this year.