The earliest air compressor was the human lung. In 1500 B.C., a new type of air compressor was invented: the bellows. Then, in 1762, professional engineer John Smeaton designed a water-wheel-driven blowing cylinder that slowly replaced the bellows. Fourteen years later, John Wilkinson’s blasting machine became the archetype for mechanical air compressors, which were being used to transmit energy by 1800.

No modern automotive shop can get by without a compressor, but if you think your shop’s compressor has an “industrial” look, you’ll be amazed by the different appearances of the compressors advertised to shop owners in the July 1924 Chilton Automobile Directory. This book had almost a full-page list of compressor suppliers, from the Acme Special Machine Mfg. Co. of Hartford, Connecticut to K.B. Wilson of Buffalo, New York.

Featured here are advertisements for three types of compressors from that directory. The Franklin Air Compressor works offered a ½-hp Super Single-Stage Compressor for $225 f.o.b. from the company’s Norristown, Pennsylvania, factory. Its features included a super-cooling spiral chamber with 2-in. fins, a patented money-saving unloader, a 300-lb. pressure gauge, bronze body globe valves and a positive safety valve.

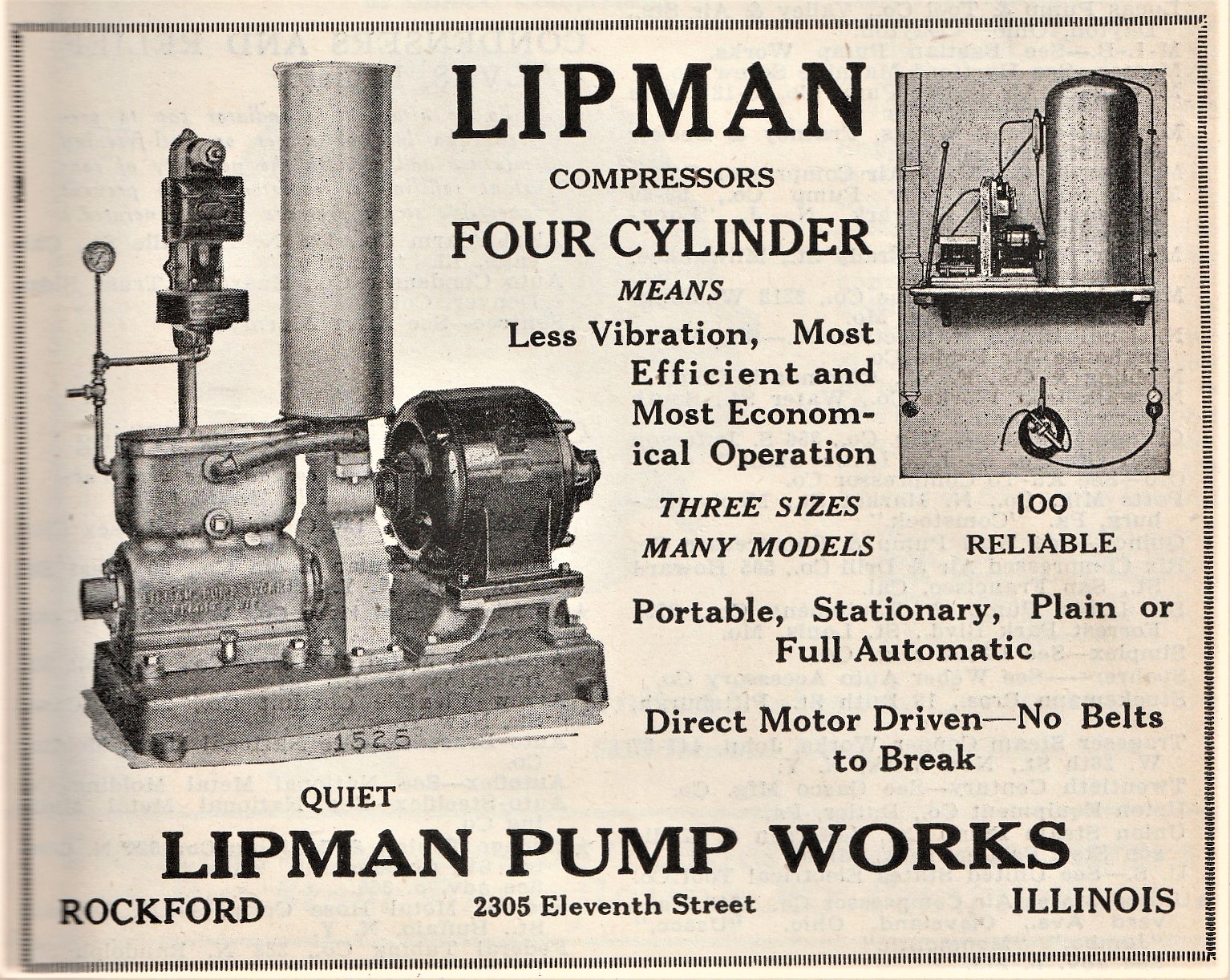

Lipman Pump Works of Rockford, Illinois, offered a direct-motor-driven four-cylinder compressor that promised quieter operation, less vibration, high efficiency and economical operation. It was available in three sizes and in portable, stationary, plain or fully automatic versions. The direct motor drive meant there were no belts to break.

Globe Mfg. Co. of Battle Creek, Michigan, said that its two-stage Globe Simplex compressors were best for tire inflation service, which was important to shops in the mid-1920s, when tire quality was marginal and cars got lots of flats. Globe said its compressors cost less, pumped more air, drew more trade and gave less trouble.