This article originally appeared in the July 2025 issue of THE SHOP magazine.

One would think a market that is all about slowing down would not be known for steadily accelerating in importance. But that’s exactly how the performance brake market is doing these days.

People are no longer treating their brake systems as afterthoughts. Instead, they are bringing brakes in early in their builds. After all, something has to counteract all that under-hood power found in today’s performance and race vehicles.

More options and specialized features mean there’s a lot to learn about today’s performance brake market. Suppliers are here to comment on market trends, sales strategies and the hottest new brake products that deliver a full stop when it’s needed.

MEETING TODAY’S CHALLENGES

As is usually the case in most areas of the aftermarket, observations on the health of the performance brakes market start with how buyers feel about the nation’s economy.

“During our first two years, everyone was dealing with the cause and effects of the pandemic. Once things loosened up, people started buying again, but the supply chain was still recovering so it was difficult to get raw materials and some components. Things started rolling in 2023 but then got tighter in 2024—most distributors saw big increases in their overall brake category but declines in sales for their premium brake products,” says Tom Reid, president and CEO of SSBC-USA. “Recently, things are picking up for American manufacturers that have reliable inventory available and are not affected by tariffs.”

As the market has evolved, insiders say brake technology has improved at both the factory and aftermarket levels. Today’s drivers expect smooth, solid stops every time.

“When someone goes to either build or have a car built, they expect more from the brake system being installed,” says Michael Hamrick, events and promotions manager at Wilwood Disc Brakes. “Along with brake components having to keep up with the times, so have the wheel, tire and suspension companies. Your ‘daily driver’ has become a much better performance vehicle than you drove 10 years ago with all the engineering that is being put into cars now.”

Brake, suspension and wheel/tire companies have also turned their attention to bringing similar performance to vehicles built in the 1960s and ’70s, he adds.

“Higher-quality manufactured parts, better and more extensive testing along with customer feedback go much further than they used to.”

Joshua Russell, from the marketing department at EBC Brakes, notes today’s cars are faster, heavier and more capable than ever—whether it’s a turbocharged hot hatch, a performance SUV or even a high-powered EV.

“This shift means the demands placed on braking systems have increased significantly, even for everyday driving. What was once considered track-only equipment is now often needed for fast road use,” Russell says. “As a result, EBC Brakes has had to adapt, offering products for a broader range of vehicles and driving styles. Ultimately, as vehicles have become more advanced, the performance aftermarket has followed suit—offering components that can keep up with today’s high demands while still delivering everyday usability.”

Mathew Roskey, USA sales manager for Disc Brakes Australia, has also seen new car and truck models prompt brake system updates.

“Vehicles today are heavier and faster from the factory than ever before. This has increased the demand for the brakes substantially, even causing the OEMs to go to a two-piece disc design,” he reports. “We also need to look at the EV platforms. In day-to-day driving the regenerative braking does most of the stopping, but when you drive the vehicle on a track or in HPDE events the speed and extra weight that is being carried due to the battery puts a high demand on the brakes. In racing we have not seen 4,000-plus-pound vehicles on track.”

Such innovations for specific market segments means more education is needed at the shop and installer levels, says Rick Elam, director of braking at Baer Brakes, part of the Holley Performance Brands portfolio.

“On the early/classics side, there are way more options for suspension and brakes, which can be good and bad,” he says. “There are more high-quality parts than ever before, but the sheer volume of options can be overwhelming, often leading to confusion and hesitation for customers. Over the years, we’ve found that it’s essential to look at the vehicle as a whole, understanding how our parts interact with and affect other systems, to ensure we deliver a complete package for the customer. We want to make sure our parts work smoothly with the rest of the vehicle and fit what the customer plans to do with it.”

Meanwhile, since most late-model vehicles come with capable brakes from the OEMs, “the aftermarket has adapted, offering upgrades that complement modern performance and take braking to the next level,” he adds.

More systems have also meant more suppliers entering the aftermarket.

“The performance brake market has grown to become diluted with options, with a few brands flattering PowerStop by imitating us. Despite this, we still see the quality of the product and brand recognition as what sets us apart,” says Jake Walenga, marketing manager at PowerStop Brakes.

Shops may be happy to hear that the folks doing brake jobs are not forgotten.

“Mirroring trends across the aftermarket, the performance brake market has undergone a significant evolution in its approach to installer-focused designs,” says Bill Cummings, president of LEED Brakes. “Today’s kits boast enhanced ease of installation, greater completeness and a wealth of embedded knowledge. Driven by years of customer feedback regarding past struggles, many companies have proactively identified and addressed these pain points in their product development.”

SLOW & STEADY

While they are seemingly straightforward systems, shops will still want to take a slow, steady approach to identifying and installing performance brakes in order to maximize efficiency and driver satisfaction.

“When it comes to performance brakes, especially on classic 1960s and ’70s vehicles with their myriads of factory brake configurations (spindles, wheels, master cylinders, boosters, etc.), thorough upfront questioning isn’t just helpful—it’s absolutely critical,” says Cummings. “Failing to meticulously gather information about the customer’s exact vehicle specifications and their long-term vision is a recipe for misdiagnosis, incorrect parts, fitment nightmares and ultimately, a dissatisfied customer. Investing the time to ask detailed questions at the outset streamlines the entire process, ensuring you guide them to the right product the first time. Furthermore, understanding their future aspirations allows you to strategically recommend current solutions that will seamlessly integrate with planned upgrades, potentially including advice on wheel and suspension compatibility.”

Walenga recommends getting to know the customer and what they expect.

“Our products not only solve issues and reduce comebacks for repair shops and mechanics but are also specifically geared toward the driving habits and application of the end user. It’s important to understand how the end user drives their vehicle to be able to recommend the correct braking solution.”

Hamrick offers a question list to get conversations started.

“What are they going to do with the car once it’s built? How and where are they going to drive it? Who is going to drive it? Will it be a daily driver? Do they plan to autocross the vehicle? Take it to an open track? Will it have big horsepower and amenities like their newer daily-driven car? Does the customer have some driving experience or are they looking to become a better driver?” he asks. “If the shop does not select parts that will meet their customers’ expectations and if these parts do not work well together, it’s a recipe for failure.”

As is the case in many segments of the specialty aftermarket, it’s important to remember that not every user needs top-of-the-line performance.

“One of the most common mistakes shops make when selling or fitting performance brake products is assuming that ‘more performance’ automatically means ‘better,’” says Russell. “It’s tempting to recommend the most aggressive pad compound or highest-spec rotor, but if those parts don’t suit the customer’s vehicle or driving style, it can lead to disappointing results—or even safety concerns. For example, fitting a race-focused pad on a daily-driven road car might result in excessive noise, poor cold bite, increased rotor wear and even reduced stopping performance during normal driving.”

Quality features and benefits make more of a lasting impact on drivers than price alone.

“Sometimes it’s hard for shops to sell value based on increased safety, more reliability and the benefits of being American made,” says Reid. “Many shops make the mistake of wanting to be price leaders and not value-added sellers.”

Another common mistake is mixing and matching parts to save a few dollars, says Elam.

“There is no such thing as a universal disc brake master or a drum master. It is matching the correct components together to work properly,” he says. “Brakes must work together—it’s a complete system.”

Finally, when it comes to actual brake installation, Roskey offers a quick checklist:

- Clean the hub for the disc to sit flush

- Properly torque the wheel

- Bed in the brakes properly

THERE’S NO STOPPING BRAKE SALES

Increasing brake system business starts with highlighting your shop’s knowledge and experience.

“Boost sales with expert service and proactive performance solutions,” says Cummings from LEED Brakes. “Elevate performance brake sales by providing thorough service that builds trust. When diagnosing brake issues, proactively educate customers on past experiences and the advantages of performance upgrades. Set clear expectations about the value of performance options. Consistently delivering on promises creates satisfied customers open to future upgrades.”

Russell from EBC Brakes suggests focusing on education and consultation rather than just parts replacement.

“Many drivers aren’t aware of the options available beyond standard OEM-style components,” he reveals. “By taking the time to ask about their driving style—whether they do track days, tow, or simply enjoy spirited driving—shops can recommend a product that genuinely enhances their experience behind the wheel. When customers understand that a properly matched pad and rotor combination can improve safety, feel and confidence—not just performance—they’re far more likely to upgrade.”

In-depth discussions lead to purchases based on value instead of price.

“So many shops and service advisors assume they are doing their customers a service recommending only the most economical options, while the vehicle owner may be more satisfied with a product that fits their driving style better,” says Walenga from Power Stop.

Those low-cost options are likely not up to the task of stopping upgraded vehicles, says Reid from SSBC-USA.

“For vehicles that have been modified or enhanced, it is important to explain that the standard OEM system was not designed to stop a vehicle with larger wheel/tires, more weight, higher engine output or any changes in the vehicle’s stance or center of gravity (height). The vehicle will behave completely differently during braking and more stopping power is usually required to ensure proper performance and safety,” he says. “For all vehicles, it is important to tell vehicle owners that they get what you pay for. If they are interested in better performance and reliability, a low-cost solution is not going to get them there.”

Meanwhile, quality systems can also be an important part of an overall performance package.

“Brakes are a common upgrade if changing rear ends or suspension,” says Elam from Baer Brakes. “At the time of sale of these parts, make sure you add the brake sale to it instead of having your customer purchase parts from another source. Early domestic cars are getting more expensive—the brakes are a safety add-on that helps protect their investment. Many customers want to upgrade but aren’t sure where to start, so be sure to educate customers on how these upgrades can make their vehicle safer and more enjoyable to drive.”

The systems make a real impact on safety and drivability, making them a logical add-on to vehicle upgrade projects.

“If the customer is having larger wheels and tires installed, talk to them about the importance of upgrading the brakes, as the increased rotational mass will have a major effect on braking performance. Or, if you are putting on a tire with more grip, let the customer know that you can add more brake torque to give the car a much-improved driving experience,” says Roskey from Disc Brakes Australia. “If the customer installs a suspension upgrade it will add additional mechanical grip, allowing you to add more stopping power without getting into the ABS. If you add weight or speed to the vehicle, it will need to have the brakes upgraded to handle the added demands.”

Once established as a local performance brake system expert, shops can then work on efficiency to minimize job times and maximize profits.

“If the shop is usually doing the same types of builds—let’s say 1965-73 Ford Mustangs—try and work on a method and process that works,” says Hamrick from Wilwood. “Which aftermarket components work well together? Which suspension manufacturers sell brakes with their systems? These must work in sync together because they offer them together. What wheel and tire size and fitment works well with this suspension and brake package selected? How does it work? Can it be tweaked to make it work better for the customer later? Can they change brake pads in the car to meet their level of driving performance a year later without having to change the brake system? Choosing the right brake kit the first time creates repeat customers and new customers that know you have a formula that works.”

PERFORMANCE BRAKES

HOT PRODUCTS: Classic Series Brake Kits

FEATURES & BENEFITS: Modern disc brakes upgrades at an affordable price; complete engineered solutions for early domestic cars; deliver value and performance by retrofitting early domestic cars with modern disc brake kits instead of stock reproduction parts.

Baer Brakes

Rick Elam

Director of Braking

HOT PRODUCTS: 4000 & 5000 Series Brake Discs

FEATURES & BENEFITS: Vane structure called the “kangaroo paw” is a unique pillar design inside the rotor that allows for more cooling and better internal strength, delivering a more consistent and stronger disc.

Disc Brakes Australia

Mathew Roskey

USA Sales Manager

HOT PRODUCTS: Redstuff Brake Pads

FEATURES & BENEFITS: Premium NAO (non-asbestos organic) ceramic granule-enhanced brake pads; low-dust formula; enhanced braking performance; reduced rotor wear; meet ECE R90 brake safety regulations; Brake-In surface coating facilitates quicker bed-in.

EBC Brakes

Joshua Russell

Marketing

HOT PRODUCTS: MaxGrip Lite 4-Piston Aluminum Caliper Front Disc Brake Conversion Kits

FEATURES & BENEFITS: Popular choice for classic and muscle car owners looking for a substantial upgrade in braking performance, safety and aesthetics; straightforward installation process; combine multi-piston caliper benefits with high-performance MaxGrip XDS rotors.

LEED Brakes

Bill Cummings

President

HOT PRODUCTS: Z36 Truck & Tow Brake Pads

FEATURES & BENEFITS: Carbon-fiber ceramic brake pad formula provides severe-duty stopping power without sacrificing everyday drivability; low dust; noise-free.

Power Stop

Jake Walenga

Marketing Manager

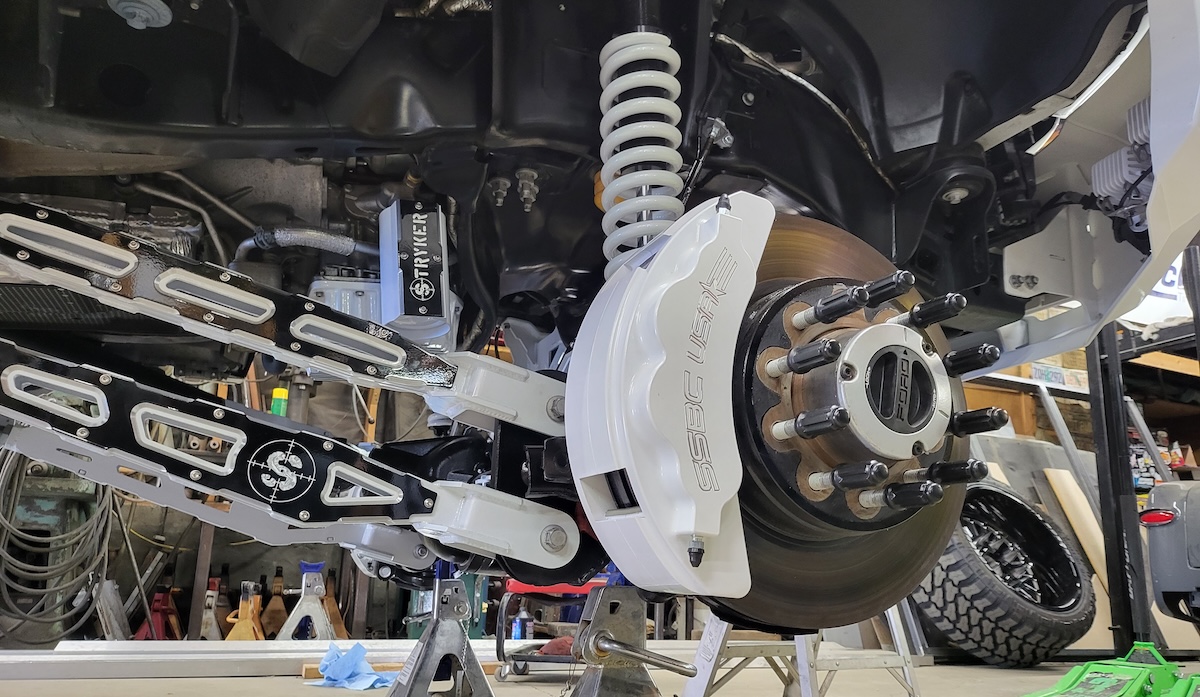

HOT PRODUCTS: Brawler-LT (Light Truck) Series for 1/2-Ton Trucks

FEATURES & BENEFITS: 100% American-made billet aluminum calipers and Dimple Drilled & Slotted (DDS) rotors; direct fit; stainless steel pistons, bleeders and pad clips; eye-catching design; Red Line series available for late-model Mustangs and American muscle cars.

SSBC-USA

Tom Reid

President/CEO/Founder

HOT PRODUCTS: Aero6-DM Direct Mount Front Brake Kits

FEATURES & BENEFITS; True front brake upgrade for many late-model 1/2-ton and midsize trucks and SUVs including Chevy, Ford, Ram, Toyota, Jeep and Mercedes-Benz Sprinter vans using 17-inch and larger wheels; forged aluminum 6-piston Aerolite calipers and one-piece vented rotors.

Wilwood Disc Brakes

Michael Hamrick

Events & Promotions Manager